Click image to zoom in

3/8 Inch Drive x 11 mm Crowfoot Wrench

Item #WCF14111

•

$12.00

Details

The Ultimate Access Tool Fits Where Others Can’t

We optimized our crowfoot wrenches for access and strength by using steel only where it matters and eliminating the excess.

Crowfoot Wrench Comparison

Performance Greatly Exceeds ASME Strength Requirements

Data from: “Category 21, Type II, Class 1 Open End, 3/8 in. Square Drive.” ASME B107.100-2020. Size 8 mm does not have a standard ASME measurement.

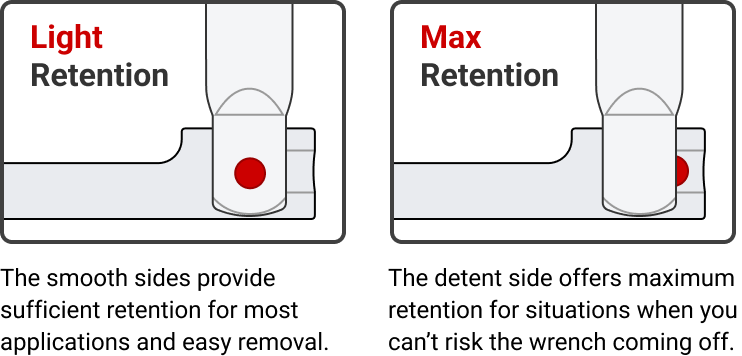

Two Levels of Retention

Clear Size Markings

The wrench sizes are laser engraved on the top surface of each wrench with a large, permanent marking that’s easy to read.

Materials and Processes

4140 Steel, Satin Nickel Finish

We make our 3/8 inch drive crowfoot wrenches from 4140 chromium-molybdenum steel and heat treat them to 50-53 HRC. The wrenches are abrasive-blasted to create a finely textured finish and then plated with nickel.

Electroless Nickel Plating

The electroless nickel plating finish is easy to wipe clean and highly resistant to corrosion.

Uniform Coverage and Better Fit

The electroless process applies a uniform coating to the entire tool surface. By comparison, electroplating, including conventional chrome plating, has varying thickness across the tool because the plating thickness depends on the electric current density at each point on the tool.

The uniformity of an electroless coating has two major advantages:

- Complete corrosion protection on interior surfaces

- Better fit in the wrench jaws because plating material does not accumulate at the jaw tips

Manufactured in Michigan

Our crowfoot wrenches are made entirely in the USA with USA-sourced materials. Machining, broaching, engraving, vibration polishing, abrasive blasting, and plating take place at our Grand Rapids, Michigan, manufacturing facility.

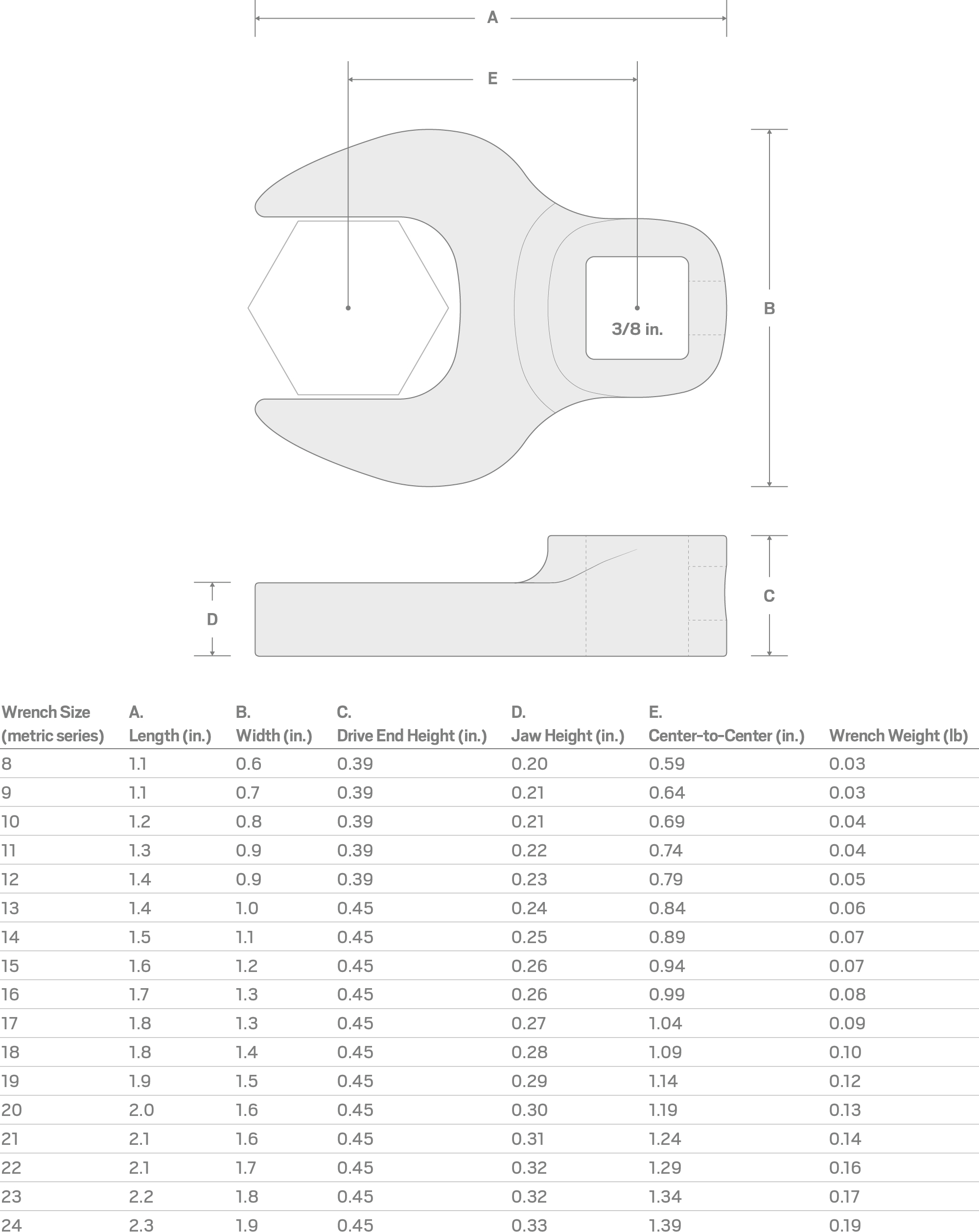

Specs

3/8 Inch Drive x 11 mm Crowfoot Wrench

| Country of Origin | United States |