We set out to make a better screwdriver handle, one that considers the ways you really work and that addresses the often-overlooked fact that your hands interact with the tool in multiple positions, not just in one standard grip. The result is curvy, contoured and likely not what you’re used to seeing. But, it's not about how it looks, it's foremost about how it works. Generous in overall size, this unique shape seamlessly blends together two key functions—torque and speed.

We start with cold drawn wire in several diameters. Screwdrivers are made from AISI 8650 steel and nut drivers from AISI 4037.

Wire is cut to length and tips are either milled on a CNC lathe or, for slotted screwdrivers, pressed and trimmed to shape. Nut drivers are formed in a cold forging process.

Controlled, consistent heat treating processes harden screwdrivers to HRC 52-56 and nut drivers to HRC 41-46.

Blades are prepared for finishing through a shot peening process that removes scale and debris and smoothes out surface imperfections.

To provide corrosion protection, blades undergo a hot black oxide conversion process. Since it’s not adding a plating layer, it can’t flake off.

A solid polypropylene handle is molded around the blade.

For a nonslip surface, a layer of soft touch material is molded around the center section of the handle.

Tekton drivers are made by a plastic injection molding technique called “insert molding” that results in a stronger and straighter driver than those manufactured by pushing a blade into a premade handle. Polypropylene plastic flows in a melted state around the steel blade, forming around every fine detail of the blade. When cooled and solidified, the resulting mechanical engagement between the handle material and the blade ensures the blade can't twist out. Because the handle is formed around the blade, rather than the blade being later forced into place, it naturally stays straight and true.

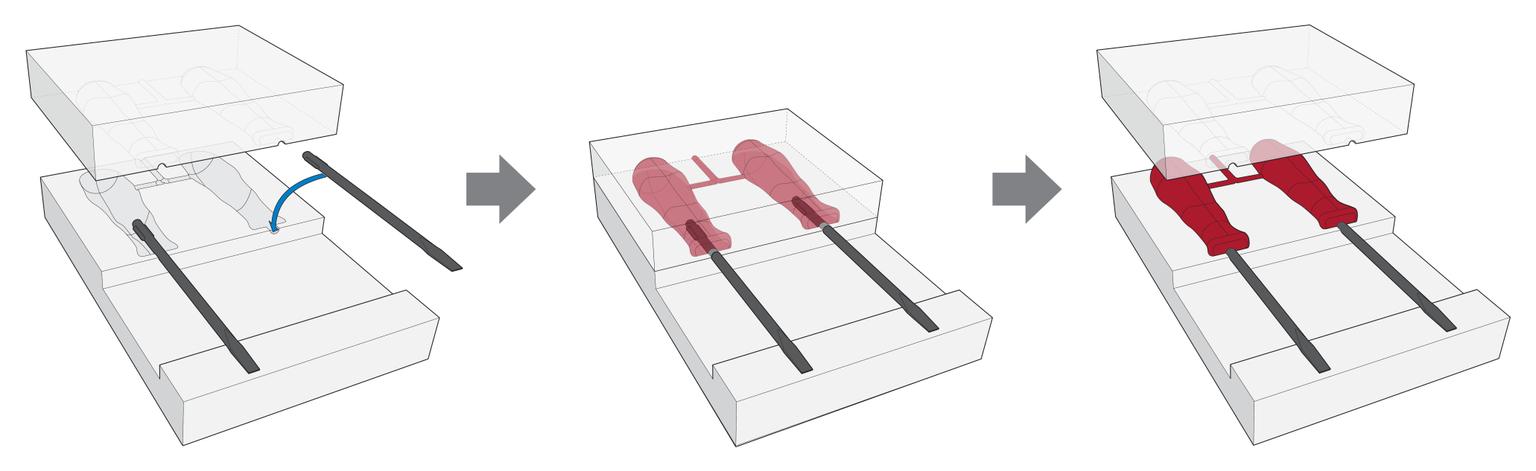

1. Blades are inserted into the mold base with their ends protruding into the handle cavity.

2. The mold base and cover close together and molten plastic is injected into each handle cavity.

3. Once packed full and solidified, the mold opens and the drivers are removed for final cooling.

We work with the best manufacturing partners to make our screwdrivers, not only traditional makers of screwdriver components, but also the leading providers in the U.S. for specific critical processes like heat treating, metal finishing, and plastic injection molding. We draw on a world-class manufacturing base in West Michigan and select partners in the eastern United States who are skilled in making products for the automotive, furniture, medical, and aerospace industries.